Guide of choosing heating adhesive laminated or glue adhesion for polykraft paper

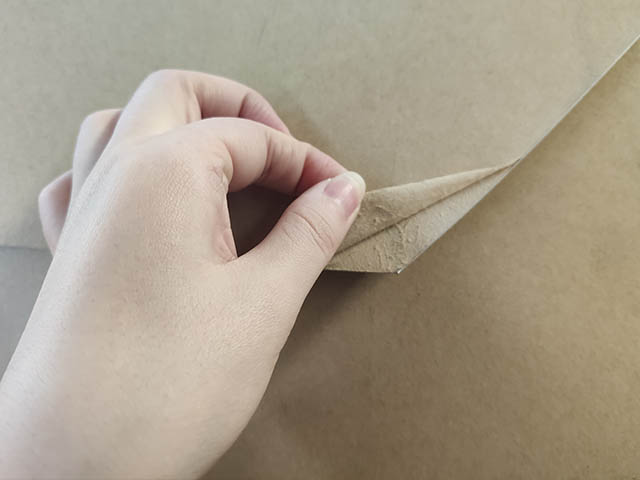

Glue adhesion: Aluminum coil and poly kraft paper are directly laminating by glue.

Advantages: High efficiency of production, timely delivery and low cost.

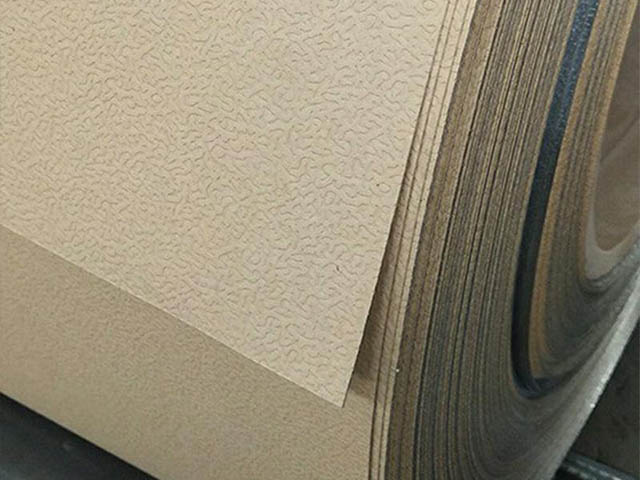

Heat adhesive laminating: Heating laminating can enhance the bonding condition between kraft paper and aluminum coil.

Other deep processing methods: Re-embossing on the composite kraft paper aluminum coil.

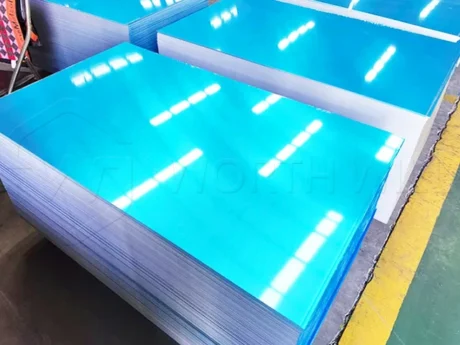

Common materials: 1060, 1050, 3003, 5052 and so on

Temper 14, 24, 16, 18 and so on.