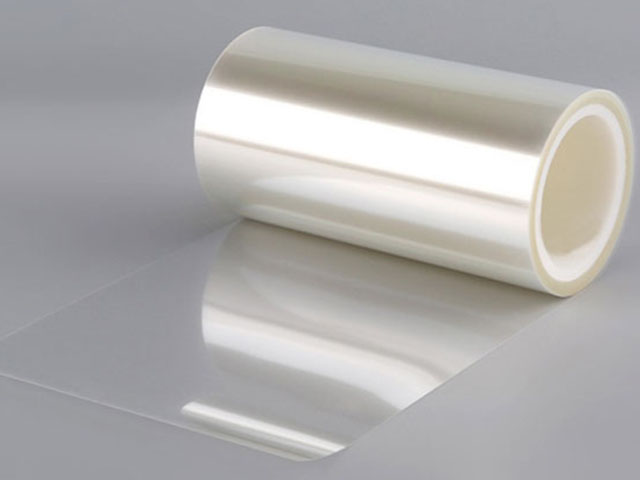

What is a PE protective film?

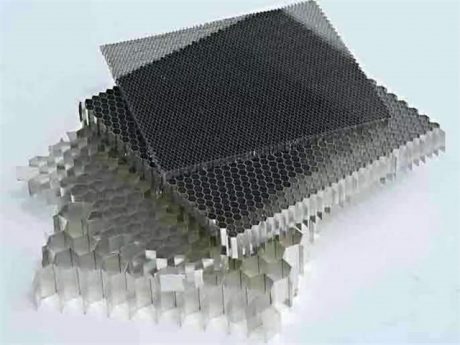

The PE protective film is a layer of plastic film attached to the aluminum material. It is mainly to protect the manufactured aluminum material from being damaged during the whole process of loading and unloading, inventory, transportation, processing, and installation.

After the aluminum material is installed later, the installation workers will tear it off to make the surface of the aluminum material as smooth as a new mouth, which will have the actual effect of the decorative design.

What are protective films made from?

The main components of PE protective film are polyethylene and acrylic glue. The protective film produced by this material can be used under normal conditions, and it is harmless to the human body and environmentally friendly.

Is it necessary to remove protective film before use?

The protective film is used to protect the product from any pollution, corrosion, damage, etc. During production, processing, transportation, storage and use, and to protect the original shiny surface of the product.

When we receive the product or prepare to use the product, we must tear off the protective film on the surface.

Taking aluminum plate as an example, aluminum plate is widely used in many industry fields, and it can be installed in a space with high temperature, such as in a kitchen. When the kitchen temperature is high, if we do not tear off the protective film, it will cause the film of the aluminum plate to become soft, wrinkle, blistering, etc., and then affect the appearance and performance of the entire product. For the long-term practicability of the aluminum plate, we must torn off the protective film.