According to the basic requirements of working, it is divided into aluminum sheet and aluminum coil.

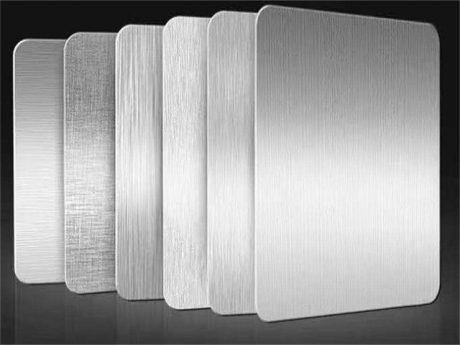

Coated aluminum sheets

PVDF coating material types is a coating of PVDF resin. The stability and firmness of this chemical structure make the physical properties of fluorocarbon coatings different from general coatings.

Benefits

Abrasion and impact resistance in terms of mechanical properties

Excellent properties in harsh climates and environments

Long-term fading and UV resistance

High temperature grilling and super weather resistance

Applications

The coating type is widely used outdoor like architecture industry. Fluorocarbon coatings can be divided into traditional fluorocarbon coatings and nano-fluorocarbon coatings according to the surface film structure.

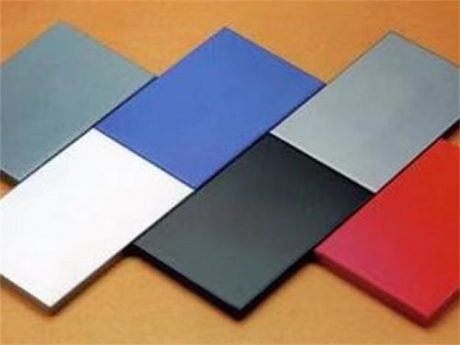

Coated aluminum coil

PE polyester coating types have protective and decorative properties, which formed by repeatedly baking and coating the surface of the aluminium sheet. It is a kind of anti-UV ultraviolet coating.

Benefits

Rich color, good gloss and smoothness

Superior texture and touch feeling

The sense of hierarchy and three-dimensionality

The coating can play a protective role.

aluminum roofing sheet

aluminum roofing sheet