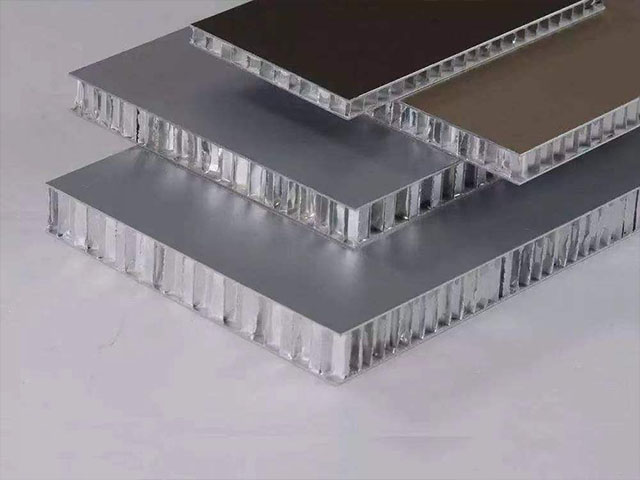

There are many advantages of products processed from honeycomb aluminum panels.

Fire prevention: Aluminum plate is not flammable and has strong fire resistance.

Corrosion resistance: The surface of the aluminum honeycomb panel is treated with epoxy fluorocarbon, which has strong corrosion resistance.

Environmental protection: The honeycomb panel is a pure aluminum product, does not emit any gas harmful to the human body, and is non-radioactive and can be completely recycled. It is an absolutely environmentally friendly product.

Easy installation: Aluminum honeycomb panels are light in weight, easy to dismantle and assemble, and the installation period is shorter than normal decoration, and the panels will not be demolished. At the same time, it is convenient to transport and can be transported to different places for repeated use.

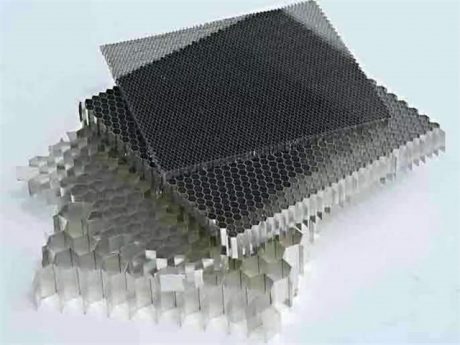

Are aluminum honeycomb panel safe?

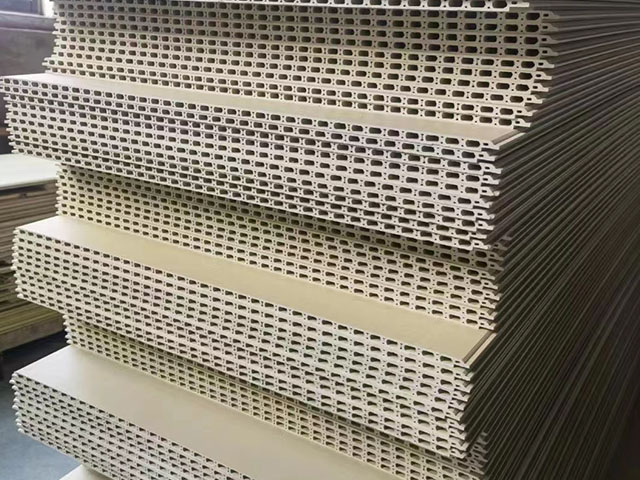

As a new type of building material, we can usually see aluminum honeycomb panels in the decoration of homes, companies or shopping malls.

The use of aluminum honeycomb panels is very safe for us. Due to its unique internal structure, it blocks the circulation of air and greatly reduces the transmission of sound and thermal conductivity. As a non-combustible material, it is fire resistant.

Aluminum honeycomb panels are not all-aluminum structures, absolutely green products, energy-saving and environmentally friendly, and will not cause harm to the human body.