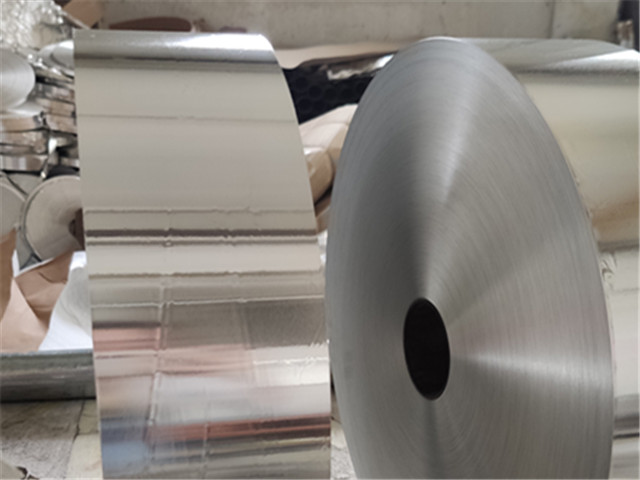

3003 Aluminum Alloy

3003 aluminum alloy is an Al-Mn alloy. The strength of the aluminum foil is slightly higher than that of commercial pure aluminum. We can’t strengthen it’s properties by heat treatment. And only cold working methods can improve its mechanical properties.

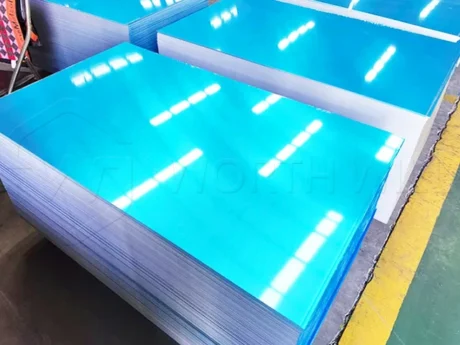

Such alloys have high plasticity in the annealed state. In addition, during cold work hardening, it has low plasticity, good corrosion resistance and good weld-ability.

3003 aluminum alloy is mainly used for parts with high requirements, plasticity and good weld-ability, such as fuel tanks, gasoline or lubricating oil conduits, various liquid containers and other small load parts made by deep drawing, etc.